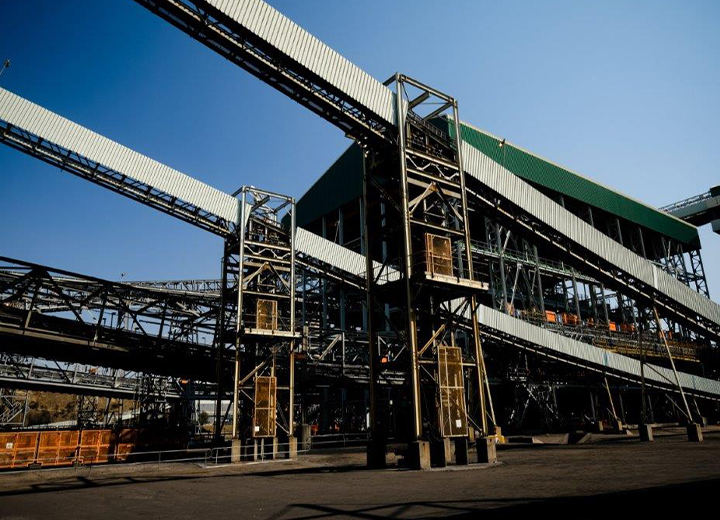

Operations

Our Minerals Strategy

Our minerals business builds from our position of strength to execute a robust strategy that is fully aligned to Exxaro’s core ambition. Exxaro Minerals plans to succeed along this journey and continue to create value for our shareholders by:

- Leveraging our deep understanding of the market and fundamental drivers of the commodities we are targeting. This strength is based on our proven market to resource strategy that has seen us grow and diversify our markets over the years, along with an optimised thermal coal product mix.

- Using our track record and experience in creating value to leverage hard-coded lessons that will guide this journey and ensure it is underpinned by a focused and rigorous set of criteria to ensure the selected commodities and targets are the right strategic fit for Exxaro.

- Playing close to our core, from our roots, in order to increase our likelihood of success, and leveraging our strengths and competencies as a coal miner rather than diversifying away from them.